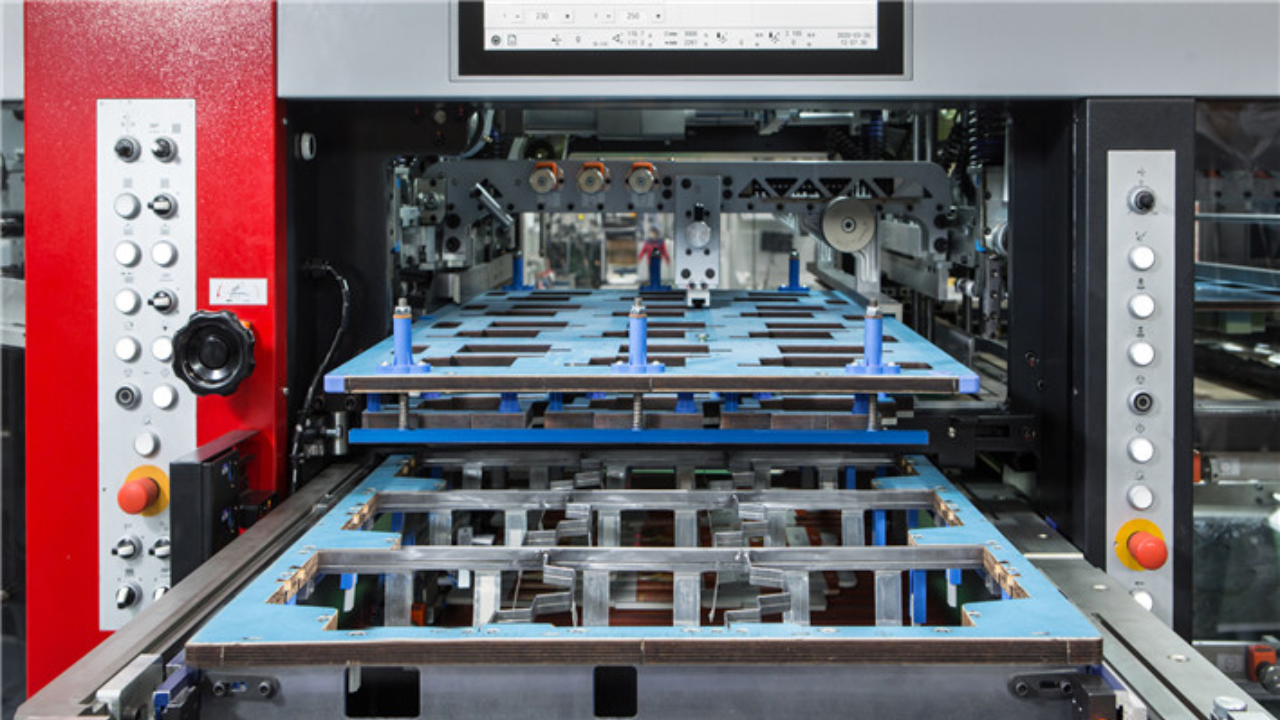

The MK Foil Stamping Machine is precisely built to provide quality performance throughout the foil stamping processes of any related projects. This machine is particularly suited for use with foil stamping, other forms of embossing, and die cutting since it provides high levels of accuracy and repeatability. It is necessary to obtain perfect results in today’s highly competitive printing industry. These are the very demands that the MK Foil Stamping Machine utilizes to incorporate advanced technology, thereby delivering reliability coupled with a high production rate.

Achieving High Precision in Every Print Job

Accuracy is always important when it comes to any form of printing. The MK Foil Stamping Machine is accurate in terms of operation due to its servo control system. This feature guarantees that the prints produced are correct, which minimizes cases of incorrect prints. Color marks, printing patterns, and paper edge detection modes ensure high-quality prints on each sheet of paper.

In order to minimize any potential physical harm and material losses the system of paper transfer is non-contact. It is important to see to it that your materials do not get scratched whenever the printer is in use since this demeans the appearance of the printed items. At this level of accuracy, you can approach any stamping task, and it can be guaranteed that the outcomes will not disappoint.

Enhanced Foil Stamping Features for Exceptional Quality

The MK Foil Stamping Machine is equipped with the latest blowing and separating system that enhances the foil control. This makes it easy to reduce instances of stamping on the wrong area, particularly for intricate designs. The optimized foil route is also very beneficial as it makes a way for the foil to run through the machine without encountering major problems hence making its operation faster.

In some larger jobs, the machine has longitudinal multi-axis foil racks and also has an improved indexing system than other models. This feature enables you to choose long foils and work with numerous foil rolls at the same time, which is suitable for extensive stamping. Each job that you are going to be involved in will have well-defined set quality levels and the quality level you will achieve will not change in the middle of the job.

MasterSet Technology: The Key to Consistency

As it has been elucidated, MasterSet technology stands out as one of the essential aspects of the MK Foil Stamping Machine. This ultrafast image sensor and enhanced detection technology guarantee the alignment of each sheet to the stamping process. Errors in alignment at this level can cause considerable problems when printing high volumes of text-based media, hence the need to maintain consistency.

The system is servo-driven, and this makes it even more precise by correcting the position of the machine based on various factors. Whether the change involves different paper types or environments, the MK Foil Stamping Machine is easily adaptable. It makes it easier to ensure that the quality of the prints is consistent to the highest level as required every time.

Two-Unit Embossing Section: Refining the Stamping Process

The two-unit embossing section in the MK Foil Stamping Machine achieves the improvement of the stamping process. In the first unit, there are 20 temperature zones with a minimum temperature of forty degrees Celsius and a maximum temperature of one hundred and eighty degrees Celsius, allowing for accurate control of the stamping temperature. This level of control is particularly helpful when working with various materials or designing intricate embossing designs.

It is also designed with a rotating gripper opening structure as well as a quick lock resin base plate that makes the machine easy to handle as well as enhances stability during operation. The honeycomb plate structure also contributes towards improving the quality of embossing due to the enhanced stamping surface. These features are collectively responsible for generating detailed, high-quality results with a relatively low amount of work.

Faultless Stripping and Blanking for Higher Productivity

There is a lot of competition when it comes to the printing business, and this is where productivity comes in. The new MK Foil Stamping Machine offers increased production through enhanced stripping and blanking areas. Quicker lock is the unique feature of the second-generation stripping tool – ease of use and fast tool replacement. This quick-change feature implies that your operations will keep on working efficiently regardless of the change of task.

The use of the pneumatic raising device in the stripping section enhances efficiency since the work is done at a faster and less strenuous method. Consequently, the blanking section is also fitted with the fine adjustment device and with the number indicator. All these sections collectively enhance waste management, optimization of the working processes and enhancement of productivity.

Conclusion

The MK Foil Stamping Machine achieves perfect productivity through accuracy, uniformity, and creativity. Sophisticated technology guarantees that any print product is done to its highest level of quality hence becoming an important equipment to any person within the printing line of work. If you’re considering foil stamping, embossing, or die-cutting, this is the machine that will give you the reliability and flexibility to succeed. The advanced technologies incorporated in the MK Foil Stamping Machine include servo control, the MasterSet technology, and effective stripping and blanking capabilities, offering a complete foil stamping solution for achieving the best result each time.