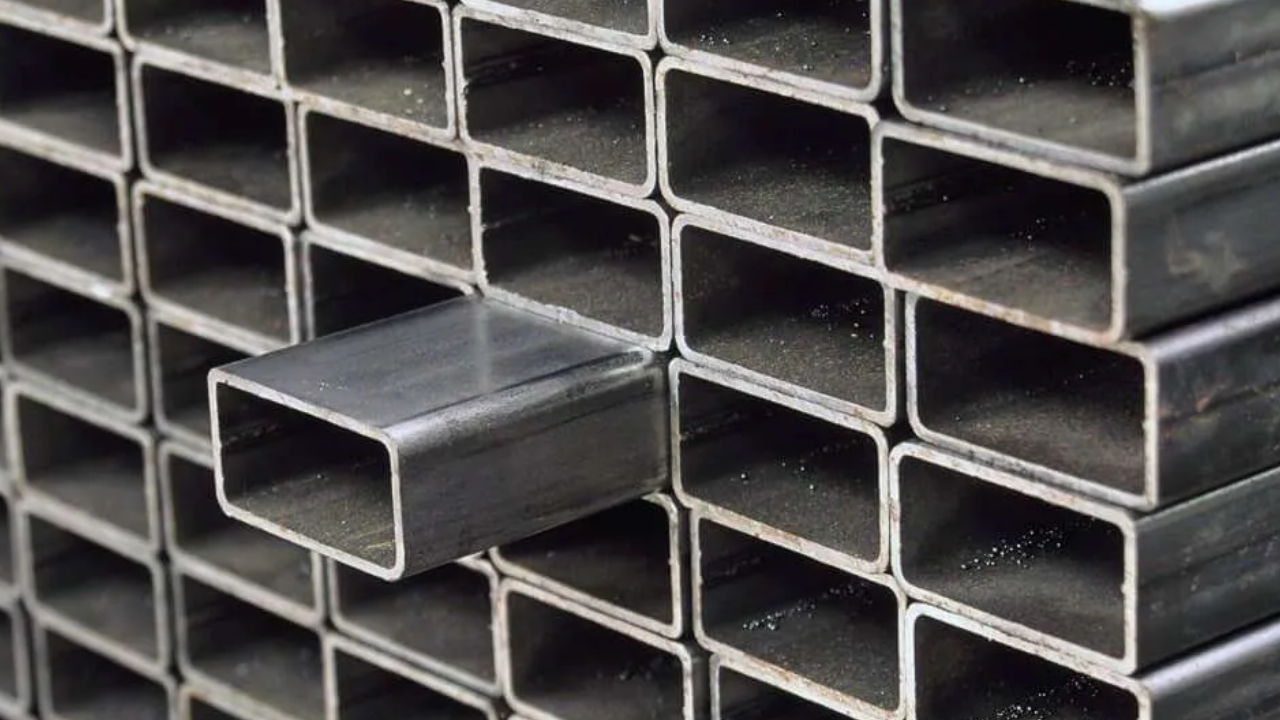

Steel pipe fittings are added substances used to associate, control, and redirect the float of steel pipes in different modern and plumbing applications. Those fittings are commonly crafted from steel to make certain durability, energy, and resistance to corrosion. They come in various sizes and styles, together with elbows, tees, reducers, couplings, and caps, amongst others, every serving a particular cause in pipeline structures.

Steel pipe fittings are vital for growing secure and leak-proof connections between steel pipes, imparting versatility and adaptability to house unique piping configurations and necessities. The steel pipe fittings are extensively used in industries inclusive of oil and fuel, production, chemical processing, and water treatment.

Common Methods for Joining Steel Pipe Fittings

Numerous techniques are typically used for joining a member of steel pipe fittings, each with its own benefits and specific applications

Threaded Connections

Threaded connections are one of the oldest and most extensively used methods for becoming a member of steel pipe fittings. This technique includes screwing collectively threaded fittings or a threaded fitting and a threaded pipe. Threaded connections are relatively easy to install and disassemble, making them suitable for applications frequent maintenance or alterations are necessary. However, they will no longer provide the same level of leak-tightness as welded connections, especially under excessive strain conditions.

Welded Connections

Welding is one more typical methodology for joining steel pipe fittings, specifically in programs where long-lasting evidence is required. While welding gives momentous strength and toughness, it requires talented work and concentrated equipment. Moreover, welding could likewise present intensity-impacted zones and remaining anxieties, that might influence the respectability of the line and fittings.

Brazing and Soldering

These techniques are usually utilized for joining more modest measurement steel pipe fittings and added substances like valves and couplings. Brazing and soldering offer benefits inclusive of lower heat entry and decreased distortion in comparison to welding. However, they will not be appropriate for high-strain or high-temperature applications due to the lower strength of the joints.

Compression Fittings

Pressure fittings are a helpful and adaptable choice for joining steel pipe fittings without the need for welding or stringing. This approach is predicated on a pressure nut and ferrule to make a tight seal between the fitting and the line. Compression fittings are smooth to put in and disassemble, making them best for applications wherein frequent preservation is required. However, they may now not be suitable for excessive-pressure or high-temperature applications, and the right tightening is essential to prevent leaks.

Flanged Connections

Flanged connections contain bolting together two flanges, with a gasket sandwiched among them to create a seal. Flanged connections are typically used in big-diameter piping structures and applications in which clean assembly and disassembly are required. They provide benefits consisting of clean alignment and the capability to accommodate misalignment or movement. However, flanged connections may be bulky and expensive, and they require a careful selection of gaskets and bolting substances to ensure leak-tightness.

Grooved Couplings

Grooved couplings are mechanical fittings that use grooves machined into the pipe ends to relax a rubber gasket and coupling housing. These fittings are quick and clean to put in, making them appropriate for packages in which rapid assembly is needed.

Summary

The selection of a joining method depends on elements together with the particular necessities of the utility, the working situations, and the available assets. By understanding the characteristics of each method, engineers and architects can choose the most suitable joining approach to ensure the reliability and efficiency of piping systems.