Poly V belts, also referred to as multi-ribbed belts, have become a subject of choice as far as the transfer of power in mechanical systems is concerned, and where machines require high efficiency with minimal space. With the shift in the industries towards smaller and lighter forms of industries, there has been an increased demand for drive systems that provide smooth, powerful, and reliable performance in smaller forms. Poly V Belt meets this challenge by offering its exclusive design, high grip, and high-speed performance, and is therefore used in the automotive, industrial, and domestic markets.

The Design of Poly V Belts

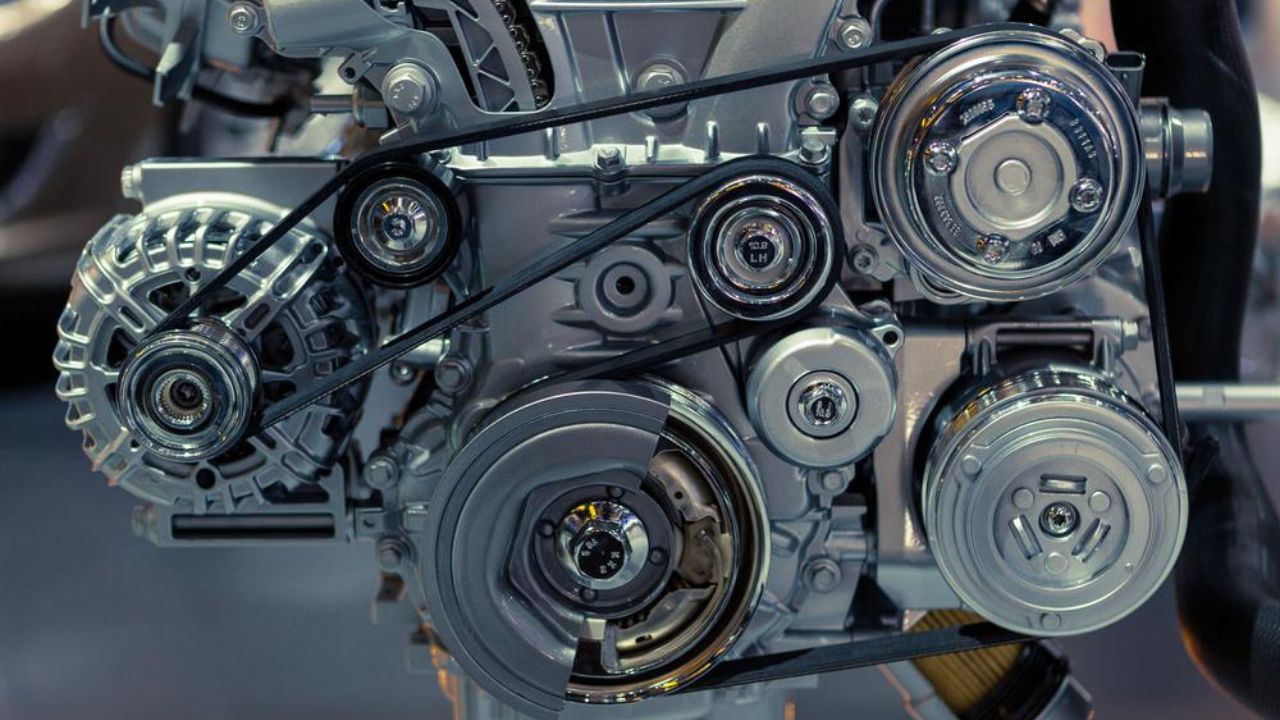

Poly V belts are distinguished by more than one longitudinal rib along the inside. These ribs are exactly inserted into the corresponding grooves of the pulleys, forming a large contact area between the pulley and the belt. This design enables effective transmission of power with minimum slip, even in the case of high speed or heavy load.

Poly V belts have the merits of both, unlike the traditional flat belts, which only use the friction of their surfaces, or the V belts, which use more space. They provide the flexibility of flat belts and the good grip of V belts, which allows them to provide a lot of power on a small drive design. The belts are normally made with strong rubber or polyurethane materials stiffened with tensile cords, which are strong, flexible, and have a long service life.

Small Dimensions and Space Saving

The fact that Poly V belts can provide high torque in a small system is one of the greatest strengths of these belts. Multi-ribbed enables the conduction of greater power per unit width in comparison with standard V belts. This implies that it can be used with a smaller diameter of pulleys and with less distance to the center without detriment to its performance.

Poly V belts are effective in industries where space is a key problem, as is the case with automotive engines, washing machines, and air conditioning compressors. Their slim and smooth shape can be used to wrap around smaller pulleys and follow complicated drive paths, thus being used in small and lightweight drive systems. Poly V belts are unique in the sense that they allow the transmission of power even in tight areas without the need to sacrifice on speed or carrying capacity.

Good Economy and Uncomplicated Running

Poly V belts are designed to be very efficient in the transmission of power. Its continuous ribbed surface gives the pulley several points of contact, and it also helps to spread the load evenly so the energy is not wasted by slip or friction. This gives a transmission efficiency of 98 percent and makes the Poly V belts one of the most energy-efficient systems among the belt systems.

They are also designed in such a way that they operate without vibration. The even interaction of ribs on the pulley grooves also minimizes the vibration and noise of belts and results in smoother and less noisy performance. This is a very useful feature, especially in automotive applications and household appliances, where comfort and precision are important features. Poly V belts offer a stable and consistent movement, which makes them reliable even with the high rotational speed and long working time.

Reduction in Maintenance and Durability

Another aspect that contributes to the preferred use of Poly V belts in the compact drive system is durability. These are heat-resistant rubber compounds combined with strong tensile cords, which make it wear-resistant, stretch-resistant, and crack-resistant. The belts are capable of withstanding high-speed rotation, acceleration, and heavy loads without major deformation.

Poly V belts produce less heat when they are being used due to their high level of flexibility, which means that they would not age easily. Also, they are more in line than several single belts, and the chances of wearing unevenly or slipping are reduced. The outcome is the longevity of the service and minimal maintenance expenses. Moreover, due to their simple design, they do not require complex tensioning or a series of parallel belt systems, and are easy to install and maintain.

Comprehensive Usage in New Systems

Poly V belts are applicable in many industries because of their functionality and efficiency. They are also used in the automotive industry in winding drive systems, which provide power to alternators, as well as air conditioning compressors and power steering pumps. They are small and hence can be designed efficiently in the contemporary engines where space is very constrained.

Poly V belts are used in industrial machinery to power compressors, pumps, and conveyor systems that require good performance in tight housings. They are also common in household gadgets, including washing machines, dryers, vacuum cleaners, and so on, in which smooth and quiet operation is critical. Poly V belts also offer the tradeoff between size and power required to sustain constant operation, even in small power tools, fitness equipment, and printing machines.

Conclusion

Flexibility, strength, and efficiency in poly V belts have transformed the transmission of power in small drive systems. They have a multi-ribbed structure, which provides maximum contact with pulleys; therefore, they can be used to provide high torque in compact spaces with no vibration or operation. Poly V belts are the best to use as industries persist in using compact systems that are more energy efficient and sustainable in terms of maintenance. They are invaluable in terms of industry as well as consumer use due to their capacity to operate at high speeds, endure wear, and reduce maintenance costs.